The Bobcat T190 is a versatile compact track loader widely used in construction and landscaping. One of the essential features of this machinery is its warning light system, which alerts operators to potential issues that may affect performance or safety. Understanding these warning lights is crucial for maintaining the loader’s functionality and ensuring operator safety.

The warning lights on the Bobcat T190 serve as an immediate visual and audible alert system. They indicate various operational statuses, including engine performance, hydraulic system conditions, and safety alerts. When a warning light illuminates, it often requires prompt attention to prevent further damage to the machine or ensure safe operation.

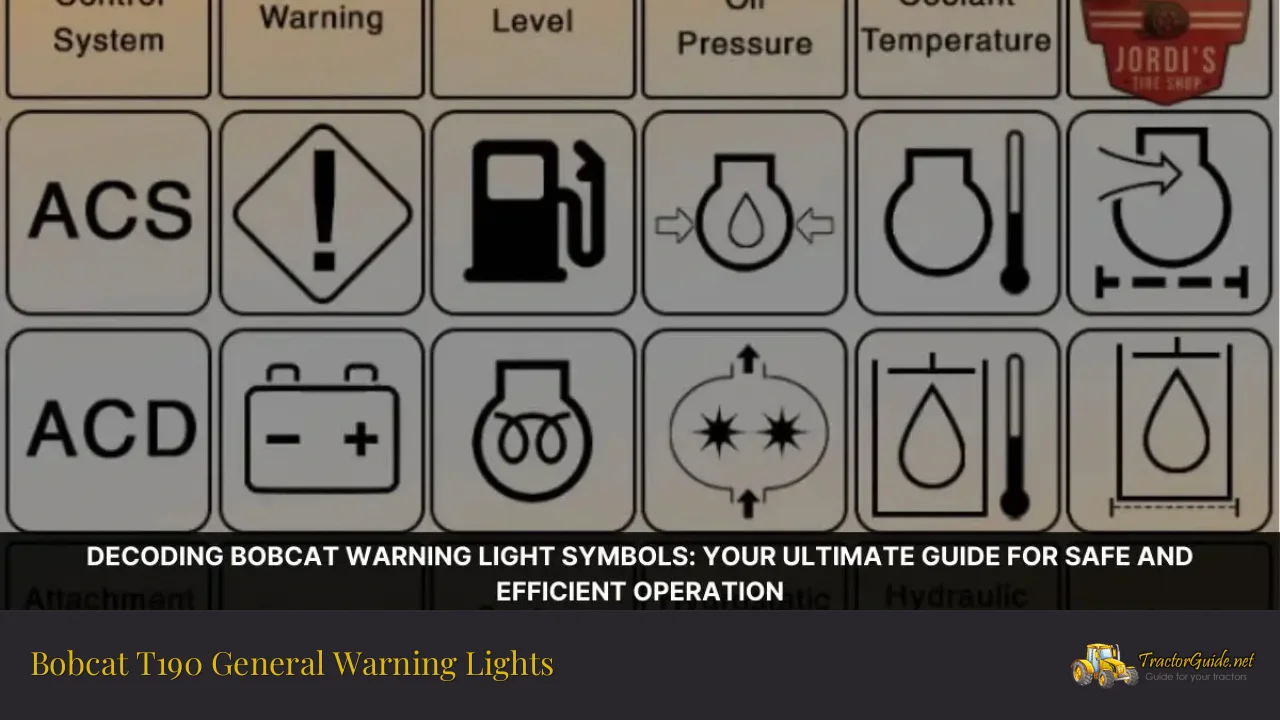

| Warning Light | Description |

|---|---|

| General Warning Light | Indicates a malfunction in engine or hydraulic systems. |

| Engine Oil Pressure | Alerts low oil pressure; immediate action required. |

| Hydraulic Oil Temperature | Indicates high hydraulic oil temperature; monitor closely. |

| Fuel Level | Indicates low fuel level; refueling needed. |

| Battery Voltage | Alerts low or high battery voltage; check battery condition. |

Understanding the Warning Lights

The warning lights on the Bobcat T190 are designed to provide real-time feedback about the machine’s operational status. Each light corresponds to specific functions and conditions that need monitoring.

When the key is turned on, all warning lights illuminate briefly as a self-check mechanism. This ensures that all lights are functional and ready to alert the operator during operation. If any of these lights remain illuminated during operation, it signals that there is an issue that needs addressing.

The General Warning Light is one of the most critical indicators on the T190. When this light activates, it signifies that there is an error with one or more engine or hydraulic functions. This could range from low oil pressure to overheating components. Ignoring this light can lead to severe damage to the engine or hydraulic systems.

Common Warning Lights and Their Meanings

General Warning Light

The General Warning Light illuminates when there is a malfunction detected in either the engine or hydraulic systems. This light may flash or stay on continuously depending on the severity of the issue.

- Flashing: Indicates a temporary fault that may resolve itself.

- Continuous: Suggests a persistent problem requiring immediate attention.

Engine Oil Pressure Light

This warning light indicates low oil pressure within the engine. If this light comes on, it is crucial to stop operating the machine immediately and check the oil levels. Low oil pressure can lead to catastrophic engine failure if not addressed promptly.

Hydraulic Oil Temperature Light

The Hydraulic Oil Temperature warning light indicates that the hydraulic fluid is overheating. Continuous operation under high temperatures can damage hydraulic components and reduce performance efficiency. Operators should reduce load and allow the system to cool down when this light activates.

Fuel Level Light

The Fuel Level warning light alerts operators when fuel levels are low. Running out of fuel can lead to air entering the fuel system, complicating restart procedures. It’s advisable to refuel at around 25% fuel capacity remaining.

Battery Voltage Light

This indicator shows when battery voltage is outside normal ranges, either too low or too high. A low battery can result in starting issues, while high voltage can damage electrical components. Operators should check battery connections and overall condition if this light activates.

Diagnosing Warning Lights

When a warning light activates, diagnosing the underlying issue promptly is essential for maintaining equipment health and safety. Here are steps operators can take:

- Stop Operation: Immediately cease operation when a warning light activates.

- Check Indicators: Refer to the operator’s manual for specific meanings of each warning light.

- Inspect Fluid Levels: Check oil, coolant, and fuel levels as most issues stem from inadequate fluid levels.

- Look for Leaks: Inspect for any visible leaks around hydraulic lines or engine components.

- Consult Diagnostic Codes: Use any available diagnostic tools to read fault codes associated with specific warnings.

Preventative Measures

To minimize the occurrence of warning lights activating during operation, operators should adhere to several preventative measures:

- Regular Maintenance: Schedule routine maintenance checks according to manufacturer guidelines.

- Fluid Checks: Regularly inspect oil, coolant, and hydraulic fluid levels before operation.

- Clean Filters: Ensure air and hydraulic filters are clean and replaced as needed.

- Monitor Performance: Be attentive to any unusual sounds or performance changes while operating.

Troubleshooting Common Issues

When faced with an illuminated warning light, troubleshooting is vital for identifying problems early:

- General Warning Light On: Check all fluid levels (oil, coolant) and inspect for leaks or unusual noises in both engine and hydraulic systems.

- Engine Oil Pressure Light On: Verify oil level; if low, add oil immediately and check for leaks.

- Hydraulic Oil Temperature Light On: Reduce load immediately; allow time for cooling before further use.

- Fuel Level Light On: Refuel as soon as possible; check for any fuel system issues if running out occurs frequently.

- Battery Voltage Light On: Inspect battery connections; consider testing battery health if problems persist.

FAQs About Bobcat T190 General Warning Lights

FAQs About Bobcat T190 General Warning Lights

- What does it mean when the general warning light comes on?

This indicates a malfunction in either engine or hydraulic systems requiring immediate attention. - How do I reset a warning light on my Bobcat T190?

Typically, restarting the machine may reset minor faults; however, consult your manual for specific reset procedures. - Why does my engine oil pressure light stay on?

This usually indicates low oil pressure; check oil levels immediately. - What should I do if my hydraulic temperature light activates?

Reduce load immediately and allow time for cooling before resuming operation. - How often should I check fluid levels?

Fluid levels should be checked before each use or daily during heavy operations.

Understanding these aspects of your Bobcat T190 will help you maintain optimal performance and extend the life of your equipment. Regular attention to warning lights not only enhances safety but also prevents costly repairs down the line.

Citations:

[1] https://www.skidsteerforum.com/threads/2007-bobcat-t190-warning-lights.115442/

[2] https://cooperequipment.ca/rental-equipment/bobcat-t190/

[3] http://lawnandgarden.manualsonline.com/manuals/mfg/bobcat/t190.html?p=26

[4] http://d3is8fue1tbsks.cloudfront.net/PDF/Bobcat/Bobcat%20T190.PDF

[5] https://www.bigrentz.com/blog/bobcat-fault-codes-list

[6] http://vejledning.materielsektionen.dk/skabelon/pdf/1784.pdf

[7] https://www.co.dakota.mn.us/Government/BudgetFinance/2017Budget/Documents/2017CEP.pdf

[8] https://www.answers.com/commercial-vehicles/What_does_an_exclamation_mark_warning_light_on_a_bobcat_mean

[9] https://www.heavyequipmentforums.com/threads/exclamation-warning-light.10211/