Caterpillar engines are renowned for their reliability and performance in various heavy-duty applications. However, like any complex machinery, they can experience issues, particularly with fuel pumps. This comprehensive guide will help you understand, diagnose, and resolve common Caterpillar fuel pump problems, ensuring your equipment operates at peak efficiency.

Understanding Caterpillar Fuel Pumps

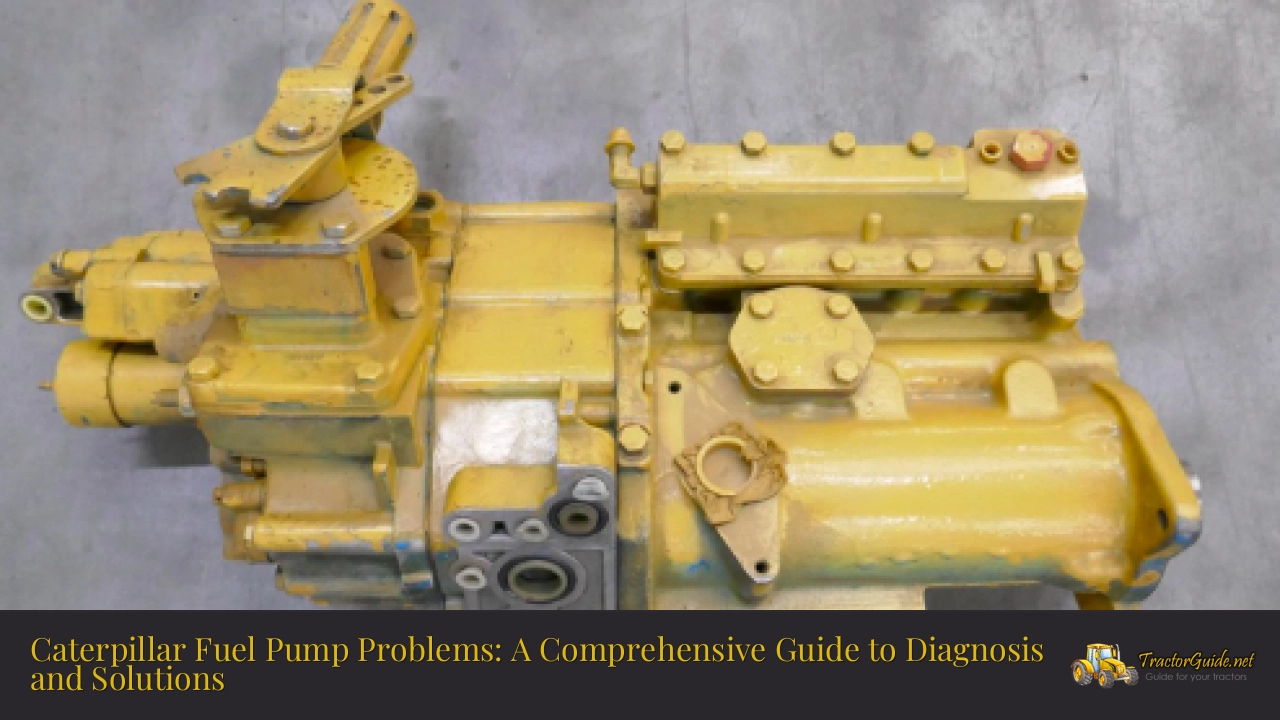

Caterpillar fuel pumps are critical components in the engine’s fuel system, responsible for delivering fuel from the tank to the engine at the correct pressure and volume. These pumps are designed to withstand the demanding conditions of heavy-duty operations, but they can still encounter issues over time.

Here’s a quick overview of the main types of Caterpillar fuel pumps:

| Pump Type | Description | Common Applications |

|---|---|---|

| Mechanical | Driven by the engine’s camshaft | Older Caterpillar models |

| Electric | Powered by the vehicle’s electrical system | Modern Caterpillar engines |

| High-Pressure Common Rail (HPCR) | Delivers fuel at extremely high pressures | Latest Caterpillar diesel engines |

Common Caterpillar Fuel Pump Problems

1. Low Fuel Pressure

Low fuel pressure is one of the most frequent issues encountered with Caterpillar fuel pumps. It can lead to poor engine performance, reduced power output, and even engine stalling.

Symptoms:

- Engine misfires or runs rough

- Difficulty starting the engine

- Loss of power, especially under load

- Increased fuel consumption

Possible Causes:

- Clogged fuel filter

- Faulty fuel pressure regulator

- Worn fuel pump

- Restricted fuel lines

Diagnosis and Solutions:

- Check and replace the fuel filter if necessary.

- Test the fuel pressure using a gauge and compare it to the manufacturer’s specifications.

- Inspect fuel lines for kinks, leaks, or blockages.

- If the issue persists, consider replacing the fuel pump or pressure regulator.

2. Fuel Pump Noise

Unusual noises coming from the fuel pump area can indicate various problems, from minor issues to impending pump failure.

Symptoms:

- Whining or buzzing sound from the fuel tank area

- Loud clicking or ticking noises

Possible Causes:

- Low fuel level

- Contaminated fuel

- Worn pump bearings

- Loose mounting bolts

Diagnosis and Solutions:

- Ensure the fuel tank is adequately filled.

- Check for fuel contamination and drain the tank if necessary.

- Inspect the pump mounting and tighten any loose bolts.

- If noises persist, the pump may need replacement.

3. Fuel Leaks

Fuel leaks not only waste fuel but can also pose serious safety hazards.

Symptoms:

- Visible fuel puddles under the vehicle

- Strong fuel odor

- Decreased fuel efficiency

Possible Causes:

- Damaged fuel lines or connections

- Cracked pump housing

- Worn seals or gaskets

Diagnosis and Solutions:

- Visually inspect all fuel lines and connections for signs of leakage.

- Check the pump housing for cracks or damage.

- Replace any worn seals or gaskets.

- If the pump housing is damaged, a full pump replacement may be necessary.

4. Intermittent Fuel Supply

An intermittent fuel supply can cause the engine to surge or stall unexpectedly.

Symptoms:

- Engine surging or stalling

- Inconsistent power output

- Difficulty maintaining constant speed

Possible Causes:

- Partially clogged fuel filter

- Faulty fuel pump relay

- Wiring issues

- Failing fuel pump

Diagnosis and Solutions:

- Replace the fuel filter.

- Check and test the fuel pump relay.

- Inspect wiring for any damage or loose connections.

- Perform a fuel pump pressure and volume test to determine if the pump is failing.

Preventive Maintenance for Caterpillar Fuel Pumps

Regular maintenance is crucial for preventing fuel pump issues and extending the lifespan of your Caterpillar engine. Here are some essential preventive measures:

- Regular Fuel Filter Replacement: Follow the manufacturer’s recommendations for fuel filter replacement intervals. This simple step can prevent many fuel system issues.

- Use High-Quality Fuel: Always use clean, high-quality fuel that meets Caterpillar’s specifications. Poor quality fuel can damage the fuel system components.

- Keep the Fuel Tank Clean: Regularly inspect and clean the fuel tank to prevent contamination from entering the fuel system.

- Monitor Fuel Pressure: Regularly check fuel pressure to catch any issues early before they lead to more significant problems.

- Inspect Fuel Lines: Routinely inspect fuel lines for signs of wear, damage, or leaks. Replace any compromised lines immediately.

- Electrical System Maintenance: Ensure the electrical system is in good condition, as many modern fuel pumps rely on proper electrical input to function correctly.

Advanced Troubleshooting Techniques

For more complex fuel pump issues, advanced diagnostic techniques may be necessary:

- Pressure Testing: Use a fuel pressure gauge to measure the pump’s output pressure. Compare the results to the manufacturer’s specifications.

- Volume Testing: Measure the volume of fuel delivered by the pump over a specific time period to ensure it meets the required flow rate.

- Electrical Testing: Check the pump’s electrical connections, relays, and fuses. Measure voltage and current draw to ensure they’re within specifications.

- Fuel Quality Analysis: If you suspect fuel contamination, consider having a fuel sample analyzed for water content, microbial growth, or other contaminants.

- Computer Diagnostics: For modern Caterpillar engines with electronic control modules (ECMs), use diagnostic software to read error codes and monitor fuel system parameters.

When to Seek Professional Help

While many fuel pump issues can be diagnosed and resolved with basic tools and knowledge, some situations require professional assistance:

- If you lack the necessary tools or expertise to safely perform diagnostics or repairs

- When dealing with high-pressure fuel systems, which can be dangerous if mishandled

- If the problem persists after attempting basic troubleshooting and repairs

- For warranty-related issues or when working on newer, more complex Caterpillar engines

Remember, improper repairs can lead to further damage or safety hazards. When in doubt, consult a certified Caterpillar technician or an experienced diesel mechanic.

Conclusion

Understanding and addressing Caterpillar fuel pump problems is essential for maintaining the performance and longevity of your engine. By familiarizing yourself with common issues, their symptoms, and basic troubleshooting techniques, you can often identify problems early and take appropriate action. Regular maintenance and the use of quality fuel and parts can prevent many issues before they occur. For complex problems or when you’re unsure, don’t hesitate to seek professional assistance to ensure your Caterpillar engine continues to operate reliably and efficiently.

FAQs

What are the main signs of a failing Caterpillar fuel pump?

Common signs include engine misfires, loss of power, difficulty starting, and unusual noises from the fuel tank area.

How often should I replace my Caterpillar fuel filter?

Follow your engine’s specific maintenance schedule, but typically every 10,000 to 15,000 miles for on-highway applications.

Can bad fuel damage my Caterpillar fuel pump?

Yes, contaminated or poor-quality fuel can cause significant damage to fuel system components, including the pump.

Is it normal for a Caterpillar fuel pump to make noise?

A slight humming noise is normal, but loud whining or clicking sounds may indicate a problem.

How long does a Caterpillar fuel pump typically last?

With proper maintenance, a Caterpillar fuel pump can last 100,000 miles or more, but lifespan varies based on operating conditions and maintenance.