Caterpillar machinery is renowned for its durability and efficiency, but like any complex equipment, it comes with its own set of warning lights that inform operators of potential issues. Understanding these warning lights is crucial for maintaining optimal performance and ensuring safety during operation. This article will explore the various Caterpillar warning lights, their meanings, and what actions to take when they illuminate.

Warning Light Meaning Red Lights Indicate serious issues requiring immediate attention Amber Lights Signal caution; issues that need monitoring

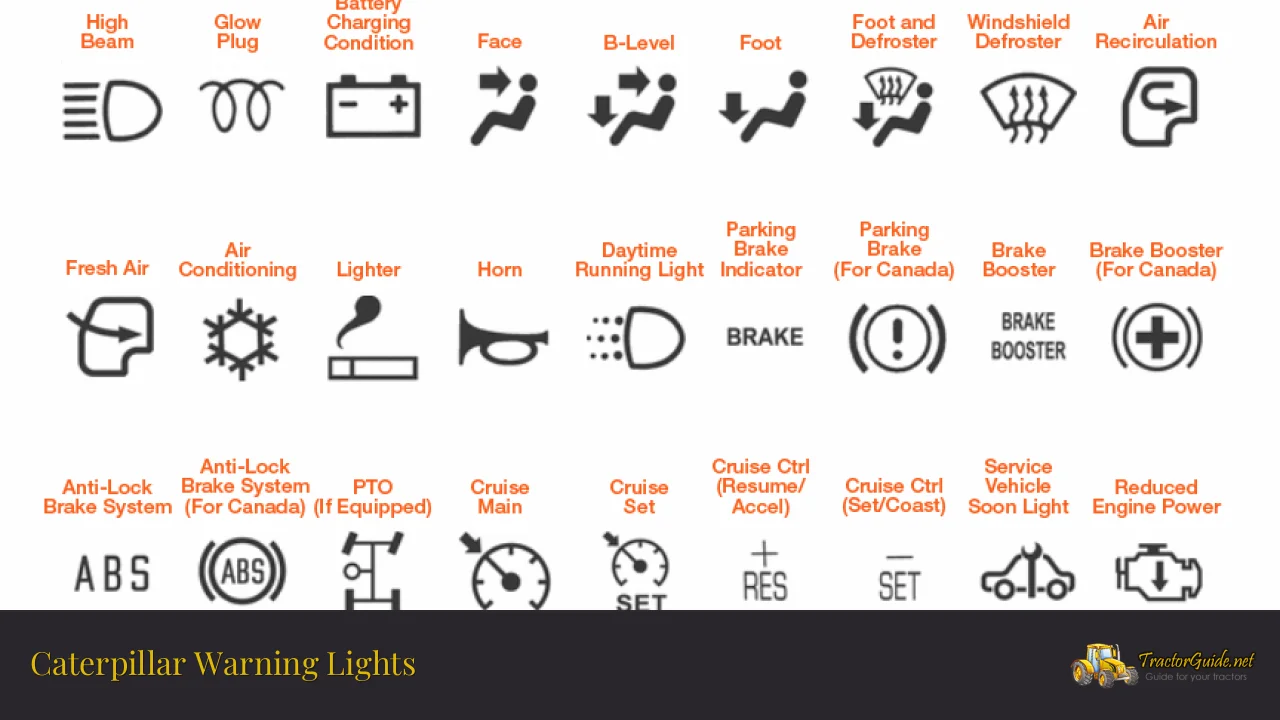

Caterpillar warning lights can appear on various models, including excavators, bulldozers, and motor graders. Each light serves a specific purpose, alerting the operator to different conditions such as low fuel, engine overheating, or hydraulic issues. Ignoring these warnings can lead to severe mechanical failures or unsafe operating conditions. Thus, it is essential for operators to familiarize themselves with these indicators.

This article will delve into the most common Caterpillar warning lights, their implications, and recommended responses to ensure safe and effective operation.

Common Caterpillar Warning Lights

Caterpillar machines are equipped with an array of warning lights that communicate vital information to the operator. Understanding these lights is essential for preventing potential damage and ensuring the safety of both the operator and the machinery.

- Engine Oil Pressure Warning Light: This light indicates that the oil pressure is below safe levels. If illuminated, check the oil level immediately and add oil if necessary. Continuous operation without sufficient oil pressure can lead to engine damage.

- Coolant Temperature Warning Light: When this light activates, it signifies that the engine coolant temperature is too high. This could indicate a coolant leak or a malfunctioning radiator. Operators should stop the machine and allow it to cool down before checking coolant levels.

- Battery Charge Warning Light: This light alerts the operator that the battery is not charging properly. It could be due to a faulty alternator or battery connections. Immediate inspection is required to avoid electrical failures.

- Hydraulic Oil Temperature Warning Light: If this light comes on, it indicates that the hydraulic oil temperature is too high. High temperatures can cause hydraulic fluid breakdown and system failure. Operators should check for leaks or blockages in the hydraulic system.

- Transmission Oil Temperature Warning Light: This indicates that the transmission fluid temperature is exceeding normal levels. Operators should reduce load and inspect the transmission system for any issues.

- Brake System Warning Light: This light signals a problem with the braking system, which could be due to low brake fluid levels or a malfunctioning brake component. Immediate action is necessary as this affects machine safety.

Understanding these warning lights helps operators take timely action to prevent equipment damage and ensure safe operation.

Actions to Take When Warning Lights Illuminate

When a warning light illuminates on a Caterpillar machine, it is crucial for operators to follow specific steps to address the issue effectively. Each light requires a different response based on its severity and implications.

- Immediate Shutdown: For red warning lights indicating critical issues (such as engine oil pressure or coolant temperature), operators should shut down the machine immediately to prevent further damage.

- Check Fluid Levels: For warnings related to fluids (like oil or coolant), operators should check levels as soon as it is safe to do so. Low levels often cause these warnings and can be easily remedied by adding the appropriate fluids.

- Inspect Components: If a warning light pertains to a specific component (like brakes or hydraulics), operators should inspect those systems for leaks, blockages, or other visible issues before resuming operation.

- Consult Manuals: Operators should refer to their specific Caterpillar Operation and Maintenance Manual for detailed troubleshooting steps related to each warning light.

- Seek Professional Help: If an operator cannot resolve the issue after performing basic checks, contacting a qualified technician or dealer is advisable for further diagnosis and repair.

Taking these actions promptly can mitigate potential risks associated with ignoring warning indicators on Caterpillar machinery.

Importance of Regular Maintenance

Regular maintenance plays a vital role in preventing warning lights from activating unnecessarily. By adhering to a structured maintenance schedule, operators can identify potential problems before they escalate into serious issues.

- Scheduled Inspections: Conducting regular inspections allows operators to catch wear and tear early on. Checking fluid levels, filters, belts, and hoses can prevent many common problems associated with Caterpillar machinery.

- Fluid Changes: Regularly changing engine oil, hydraulic fluid, and coolant helps maintain optimal performance and reduces the likelihood of overheating or pressure-related issues that trigger warning lights.

- Component Replacement: Keeping an eye on components known for wear—such as filters and seals—ensures they are replaced before they fail. This proactive approach minimizes downtime caused by unexpected repairs.

- Operator Training: Ensuring that all operators are trained in recognizing warning lights and understanding their implications can significantly enhance safety and equipment longevity.

By prioritizing maintenance, operators can reduce operational risks associated with malfunctioning equipment while extending the life of their machinery.

Troubleshooting Common Warning Light Issues

When faced with illuminated warning lights on Caterpillar machinery, troubleshooting becomes necessary to identify underlying problems effectively. Here are common troubleshooting steps based on specific warning indicators:

- Engine Oil Pressure Light: Check oil levels first; if low, add oil. If levels are adequate but the light remains on, inspect for leaks in lines or seals that could lead to pressure loss.

- Coolant Temperature Light: Ensure coolant levels are sufficient; if they are low, refill with appropriate coolant mixture. Inspect hoses for leaks or clogs that may hinder coolant flow.

- Battery Charge Light: Check battery connections for corrosion or looseness; clean terminals if needed. Test alternator functionality if connections are secure but charging issues persist.

- Hydraulic Oil Temperature Light: Inspect hydraulic fluid levels; if low, refill with recommended fluid type. Check hoses for kinks or blockages that may restrict flow or cause overheating.

- Brake System Light: Inspect brake fluid levels; if low, refill immediately. Check brake lines for leaks or damage that could compromise braking effectiveness.

Following these troubleshooting steps helps operators quickly identify problems associated with activated warning lights while ensuring safe operation of their machines.

FAQs About Caterpillar Warning Lights

FAQs About Caterpillar Warning Lights

- What does a red warning light mean?

A red warning light indicates a serious issue requiring immediate attention. - How do I reset my Caterpillar warning lights?

Resetting typically involves addressing the underlying issue; consult your manual for specific procedures. - What should I do if multiple warning lights are on?

Shut down the machine immediately and inspect each system corresponding to the illuminated lights. - Can I continue operating my machine with an amber light on?

While amber lights indicate caution, you should monitor the situation closely and address any underlying issues promptly. - Where can I find more information about my specific model’s warning lights?

Refer to your Caterpillar Operation and Maintenance Manual for detailed information about your model’s indicators.

Understanding Caterpillar warning lights is essential for maintaining equipment safety and reliability. By recognizing what each light signifies and taking appropriate actions when they illuminate, operators can ensure their machines operate efficiently while minimizing risks associated with mechanical failures. Regular maintenance further enhances equipment longevity while reducing instances of unexpected warnings during operation.

Citations:

[1] https://www.topgear.com/car-news/top-gear-advice/heres-what-all-those-dashboard-warning-lights-mean

[2] https://www.semrush.com/blog/how-to-identify-intent-in-search/

[3] https://hammerhire.com.au/assets/files/hire-excavators/cat-operator-manual-349f-352f.pdf

[4] https://www.youtube.com/watch?v=x50qcaHzNy8

[5] https://www.cat.com/en_US/articles/for-owners/introducing-your-140-150-160-motor-grader-monitor.html

[6] https://developer.android.com/guide/components/intents-common.html

[7] https://community.heavyvehicleinspection.com/thread/caterpillar-d4h-warning-light-help

[8] https://www.cat.com/en_US/articles/for-owners/articulated-truck-display-screens.html