Kubota engines are widely used in various agricultural and construction machinery, and they are equipped with Diesel Particulate Filters (DPFs) to comply with stringent emissions regulations. While these filters play a crucial role in reducing harmful emissions, they can also present several challenges for users. Understanding the common DPF problems associated with Kubota engines is essential for maintaining optimal performance and minimizing downtime.

DPF issues often arise from soot and ash buildup, which can lead to increased back pressure, reduced engine efficiency, and even engine failure if not addressed promptly. Users typically seek information on how to identify these problems, the implications of neglecting DPF maintenance, and practical solutions to mitigate issues. This article will explore common DPF problems faced by Kubota users, practical maintenance tips, and solutions to enhance the longevity of these filters.

| Common DPF Problems | Implications |

|---|---|

| Soot buildup | Increased back pressure |

| Ash accumulation | Reduced engine performance |

| Failed regenerations | Engine shutdowns |

Understanding DPF Functionality and Issues

The Diesel Particulate Filter is designed to capture soot particles from the exhaust gas of diesel engines. Over time, as the engine operates, these particles accumulate within the filter. To maintain efficiency, the DPF must undergo a process called regeneration, where the accumulated soot is burned off at high temperatures.

However, several factors can contribute to DPF problems:

- Infrequent use: Equipment that is used only intermittently may not reach the necessary temperatures for effective regeneration. This can lead to excessive soot buildup.

- Short operating cycles: Frequent short trips prevent the engine from reaching optimal operating temperatures, inhibiting proper regeneration.

- Fuel quality: Poor-quality fuel can lead to incomplete combustion, resulting in higher soot production.

- Mechanical issues: Faulty sensors or exhaust systems can prevent proper monitoring and functioning of the DPF system.

Neglecting these issues can lead to serious implications such as reduced engine power, increased fuel consumption, and potential engine damage.

Maintenance Tips for Kubota DPFs

To ensure that your Kubota engine operates efficiently and to extend the life of your DPF, regular maintenance is crucial. Here are some practical maintenance tips:

- Regular inspections: Periodically check the DPF for signs of damage or excessive buildup. Look for warning lights on the dashboard indicating DPF issues.

- Scheduled regeneration: Familiarize yourself with your machine’s regeneration cycle. If your equipment frequently requires regeneration, consider scheduling it during less busy times to avoid downtime.

- Use quality fuel: Always use high-quality diesel fuel that meets specifications. This helps minimize soot production and ensures better combustion efficiency.

- Monitor engine load: Operating under appropriate loads helps maintain higher exhaust temperatures, facilitating effective regeneration.

- Follow manufacturer guidelines: Adhere strictly to Kubota’s maintenance schedule for your specific model. Regular cleaning and servicing are essential for optimal performance.

By implementing these maintenance strategies, you can significantly reduce the likelihood of encountering DPF problems with your Kubota equipment.

Troubleshooting Common DPF Issues

When faced with DPF-related issues, it’s essential to troubleshoot effectively. Here are some common symptoms of DPF problems along with potential solutions:

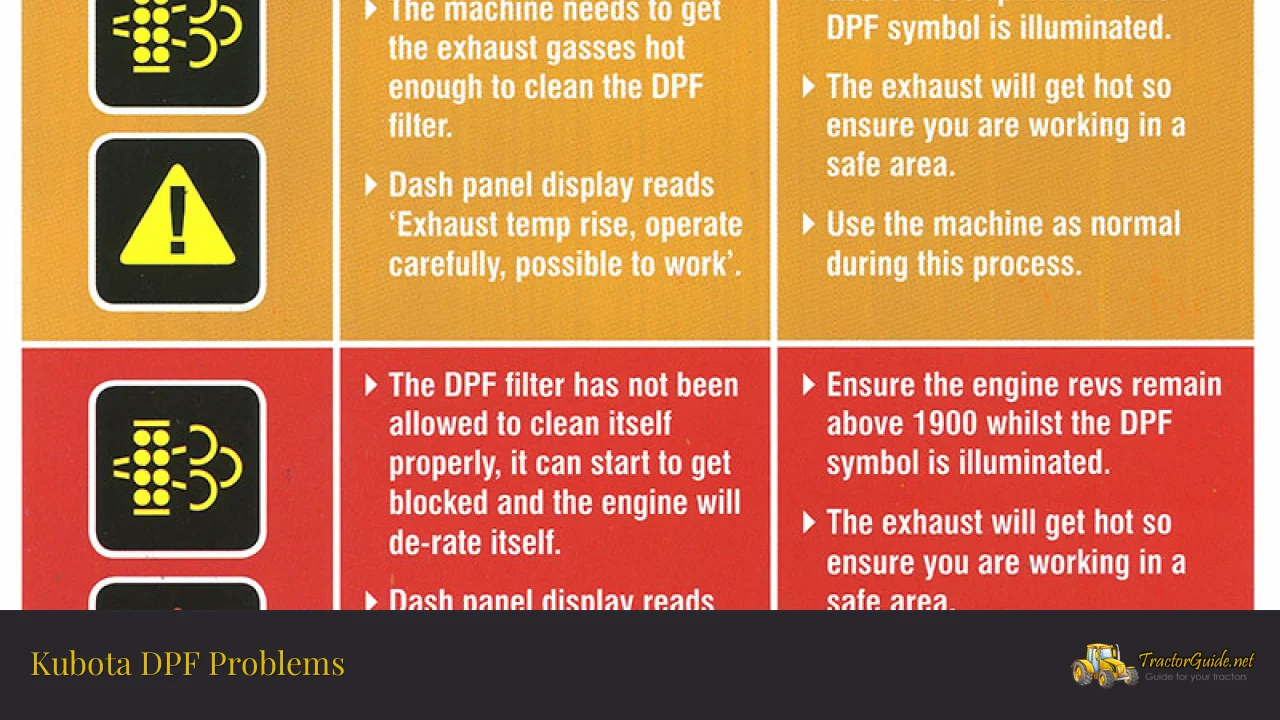

- Warning lights illuminated: If the DPF warning light comes on, it indicates that regeneration is needed. You should initiate a manual regeneration if automatic regeneration fails.

- Frequent regenerations: If your machine requires regeneration every few hours of operation, consider evaluating your usage patterns. Increasing operational loads or longer run times may help achieve effective regeneration intervals.

- Poor performance or power loss: If you notice a significant drop in engine performance or power output, it may be due to excessive back pressure from a clogged DPF. In this case, immediate cleaning or replacement may be necessary.

- Excessive smoke or emissions: Increased smoke or visible emissions can indicate incomplete combustion or a failing DPF. Investigate potential mechanical issues affecting combustion efficiency.

For persistent problems that cannot be resolved through basic troubleshooting, consulting a qualified technician or Kubota dealer is advisable.

Cleaning and Replacing Your DPF

Cleaning or replacing a clogged DPF can be an essential part of maintaining your Kubota engine’s performance. Here’s how you can approach this task:

- DPF cleaning program: Kubota offers a comprehensive DPF Cleaning Program, which includes professional cleaning services that restore filter functionality without replacement. This service involves pneumatic cleaning and thermal treatments designed specifically for Kubota filters.

- DIY cleaning options: For those comfortable with hands-on maintenance, there are DIY cleaning kits available that allow you to clean your DPF at home. However, ensure you follow all safety guidelines and manufacturer instructions carefully.

- Replacement kits: If cleaning is not an option due to severe damage or excessive ash buildup (typically after around 3,000 hours of operation), consider investing in a replacement kit from an authorized dealer. Replacement kits often come with all necessary components for easy installation.

Regularly engaging in these practices will help maintain optimal performance levels while extending the lifespan of your Kubota’s DPF system.

The Role of Technology in Managing DPF Problems

Advancements in technology have provided new tools for managing and mitigating DPF issues effectively. Here are some technologies currently available:

- DPF emulators: These devices can help bypass certain sensor readings related to DPF functionality. While they may provide temporary relief from warning lights or performance issues, using emulators may void warranties and is generally not recommended for compliance with emissions regulations.

- Diagnostic tools: Utilizing advanced diagnostic tools allows technicians to accurately assess the condition of the DPF system and identify underlying issues quickly. These tools provide valuable data on exhaust temperatures, pressure differentials, and more.

- Monitoring systems: Some modern machines come equipped with real-time monitoring systems that alert operators when maintenance is required or when regeneration is needed. These systems enhance operational efficiency by preventing unexpected breakdowns.

Investing in such technologies can significantly improve your ability to manage DPF-related challenges effectively while ensuring compliance with environmental standards.

FAQs About Kubota DPF Problems

- What causes frequent regeneration in Kubota tractors?

Frequent regenerations are often caused by short operating cycles or low engine loads that prevent reaching optimal temperatures. - How often should I clean my Kubota DPF?

The frequency of cleaning depends on usage; however, it’s recommended every 3000 hours or when warning indicators appear. - Can I drive my Kubota tractor if the DPF light is on?

It’s advisable to address any warning lights immediately as ignoring them can lead to further damage. - What happens if I ignore my DPF problems?

Ignoring DPF issues can result in reduced engine performance, increased fuel consumption, and potential engine failure. - Are there any alternatives to using a DPF?

While some users consider removing or bypassing the DPF system entirely, this is illegal in many jurisdictions due to emissions regulations.

By understanding common Kubota DPF problems and implementing proactive maintenance strategies, users can ensure their equipment operates efficiently while minimizing downtime and repair costs. Regular inspections combined with timely cleaning or replacements will ultimately enhance both productivity and longevity of your machinery.

Citations:

[1] https://www.kubotaengine.com/dpf-cleaning-program/

[2] https://thefarmingforum.co.uk/index.php

[3] https://www.sailteknoloji.com/en/dpf-emulators/251-kubota-dpf-emulator.html

[4] https://www.bobbyfordkubota.com/what-is-dpf-kubota-diesel-particulate-filter-cleaning/

[5] https://www.kubota.com/innovation/report/no55.html

[6] https://www.kubotaengine.com/your-dpf-cleaning-guide-from-kubota/

[7] https://www.reddit.com/r/kubota/comments/1cpuo3j/kubota_emissions/

[8] https://www.kubota.com/ir/financial/integrated/data/report2020_28.pdf