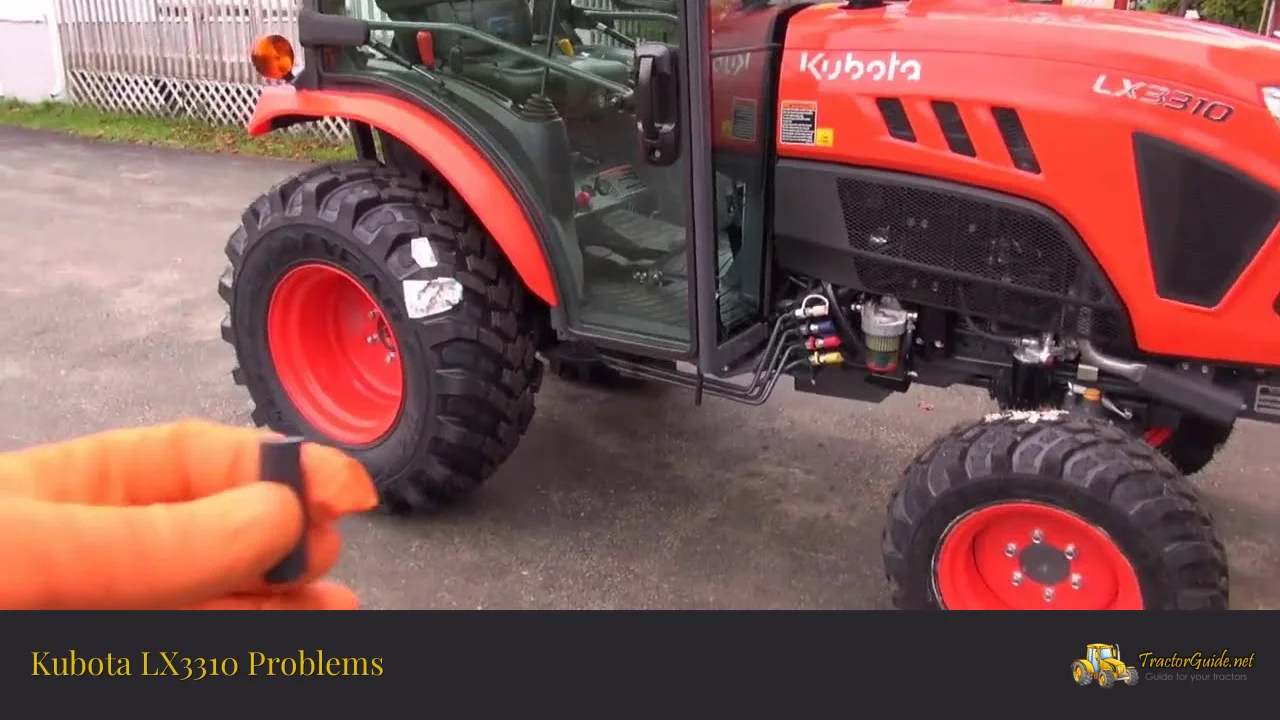

The Kubota LX3310 is a compact tractor known for its versatility and reliability in various tasks, including landscaping, farming, and construction. However, like any machinery, it can encounter problems that may hinder its performance. Understanding these issues is crucial for maintaining the tractor’s efficiency and longevity. This article will explore common problems associated with the Kubota LX3310, their causes, and practical solutions to help owners troubleshoot effectively.

Common Problems Potential Causes Starting Issues Battery failure, clogged fuel filters Engine Overheating Low coolant levels, clogged radiator Power Loss Clogged fuel filters, air intake issues Hydraulic System Problems Low fluid levels, leaks Transmission Difficulties Low transmission fluid, mechanical faults

Common Problems with the Kubota LX3310

The Kubota LX3310 is generally well-regarded among users, but it is not without its share of common problems. These issues can range from minor inconveniences to more significant operational setbacks. Below are some of the most frequently reported problems and their solutions.

Starting Issues

One of the most common complaints from LX3310 owners is difficulty starting the engine. This problem can stem from several factors:

- Battery Failure: A weak or dead battery is often the primary culprit. Ensure that the battery is fully charged and that connections are clean and secure.

- Clogged Fuel Filters: If the fuel filter is blocked, it can restrict fuel flow to the engine. Regularly inspect and replace fuel filters as part of routine maintenance.

- Faulty Glow Plugs: In colder climates, malfunctioning glow plugs can prevent proper engine ignition. Testing and replacing faulty glow plugs can resolve this issue.

To address starting issues effectively:

- Check the battery charge and connections.

- Inspect and replace clogged fuel filters.

- Test glow plugs for functionality.

Engine Overheating

Overheating is another significant issue that can affect the LX3310’s performance. Several factors contribute to this problem:

- Low Coolant Levels: Insufficient coolant can lead to overheating. Regularly check coolant levels and top off as necessary.

- Clogged Radiator: Debris accumulation on radiator fins can impede airflow. Clean the radiator regularly to ensure optimal cooling.

- Faulty Water Pump or Thermostat: If the water pump or thermostat fails, it can disrupt coolant circulation. Inspect these components during routine maintenance.

To prevent overheating:

- Monitor coolant levels frequently.

- Clean radiator fins to maintain airflow.

- Inspect water pump and thermostat for proper operation.

Power Loss

Power loss during operation can significantly impact productivity. Common causes include:

- Clogged Fuel Filters: Similar to starting issues, blocked fuel filters can reduce engine power. Ensure regular replacement of filters.

- Air Intake Blockages: Dust and debris can obstruct air intake systems. Regularly clean air filters to maintain proper airflow.

To mitigate power loss:

- Replace clogged fuel filters promptly.

- Keep air intake systems clean and free of debris.

Hydraulic System Problems

The hydraulic system is essential for various functions in the LX3310. Users may experience:

- Slow Response or Leaks: Low hydraulic fluid levels or leaks can hinder performance. Regularly check fluid levels and inspect for leaks around hoses and fittings.

To maintain hydraulic system efficiency:

- Ensure hydraulic fluid is at appropriate levels.

- Address any leaks immediately by replacing damaged hoses or fittings.

Transmission Difficulties

Transmission issues can manifest as difficulty shifting gears or unusual noises during operation. Potential causes include:

- Low Transmission Fluid: Insufficient fluid can lead to shifting problems. Regularly check transmission fluid levels and top up as needed.

- Mechanical Faults: Worn components within the transmission may require professional servicing if problems persist despite adequate fluid levels.

To resolve transmission difficulties:

- Monitor transmission fluid levels regularly.

- Consult a professional if shifting issues continue after checking fluid levels.

Maintenance Tips for Preventing Problems

Regular maintenance plays a crucial role in preventing many of the common problems associated with the Kubota LX3310. Here are some essential maintenance tips:

Routine Checks

Perform routine checks every 50 hours of operation or as recommended in the owner’s manual:

- Inspect oil levels (engine and hydraulic).

- Check coolant levels.

- Clean or replace air filters as needed.

Seasonal Maintenance

Before heavy use in different seasons, consider performing additional checks:

- In winter, ensure that all fluids are suitable for low temperatures.

Use Quality Parts

When replacing parts such as filters or fluids, always opt for genuine Kubota parts to ensure compatibility and reliability.

Troubleshooting Steps for Common Issues

If you encounter specific problems with your Kubota LX3310, follow these troubleshooting steps:

Starting Issues Troubleshooting

1. Check battery charge; replace if necessary.

2. Inspect fuel filters; replace if clogged.

3. Test glow plugs; replace any faulty ones.

Overheating Troubleshooting

1. Verify coolant levels; refill if low.

2. Clean radiator fins; remove any debris.

3. Inspect water pump and thermostat; replace if faulty.

Power Loss Troubleshooting

1. Replace clogged fuel filters.

2. Clean air intake systems regularly.

Hydraulic Issues Troubleshooting

1. Check hydraulic fluid levels; top up if low.

2. Inspect hoses for leaks; repair as needed.

Transmission Troubleshooting

1. Check transmission fluid levels; add if necessary.

2. Consult a professional if shifting difficulties persist.

FAQs About Kubota LX3310 Problems

FAQs About Kubota LX3310 Problems

- What should I do if my Kubota LX3310 won’t start?

Check the battery for charge and ensure terminals are clean. - How often should I change the hydraulic fluid in my LX3310?

Typically every 400 to 600 hours of operation or annually. - Why does my Kubota LX3310 overheat?

This may be due to low coolant levels or a clogged radiator. - How do I maintain the PTO system?

Lubricate the PTO shaft and check for debris regularly. - What are signs of a failing transmission in the LX3310?

Difficulties shifting gears or unusual noises indicate potential issues.

In conclusion, while the Kubota LX3310 is a reliable machine, being aware of common problems and their solutions can help owners maintain optimal performance. Regular maintenance practices are essential in preventing many of these issues from arising in the first place. By staying proactive about care and troubleshooting effectively when problems occur, users can ensure their LX3310 remains a dependable workhorse for years to come.

Citations:

[1] https://www.youtube.com/watch?v=vMeKK8fhqxM

[2] https://www.orangetractortalks.com/forums/threads/new-lx-3310.51010/page-3

[3] https://www.youtube.com/watch?v=LDe5_Vrh7GI

[4] https://mrmotorproblems.com/kubota-lx3310-problems/

[5] https://www.orangetractortalks.com/forums/threads/kubota-lx3310-been-in-shop-for-the-past-3-weeks.55473/

[6] https://www.kubotabooks.com/AutoIndex/index.php?dir=Tractor+Owners+Manuals%2F&file=LX2610-LX3310+OPS.pdf

[7] https://vehiclesanswer.com/kubota-lx3310-problems/

[8] https://www.youtube.com/watch?v=qCUnZzGOads

[9] https://farmsunseed.com/kubota-lx3310-problems/