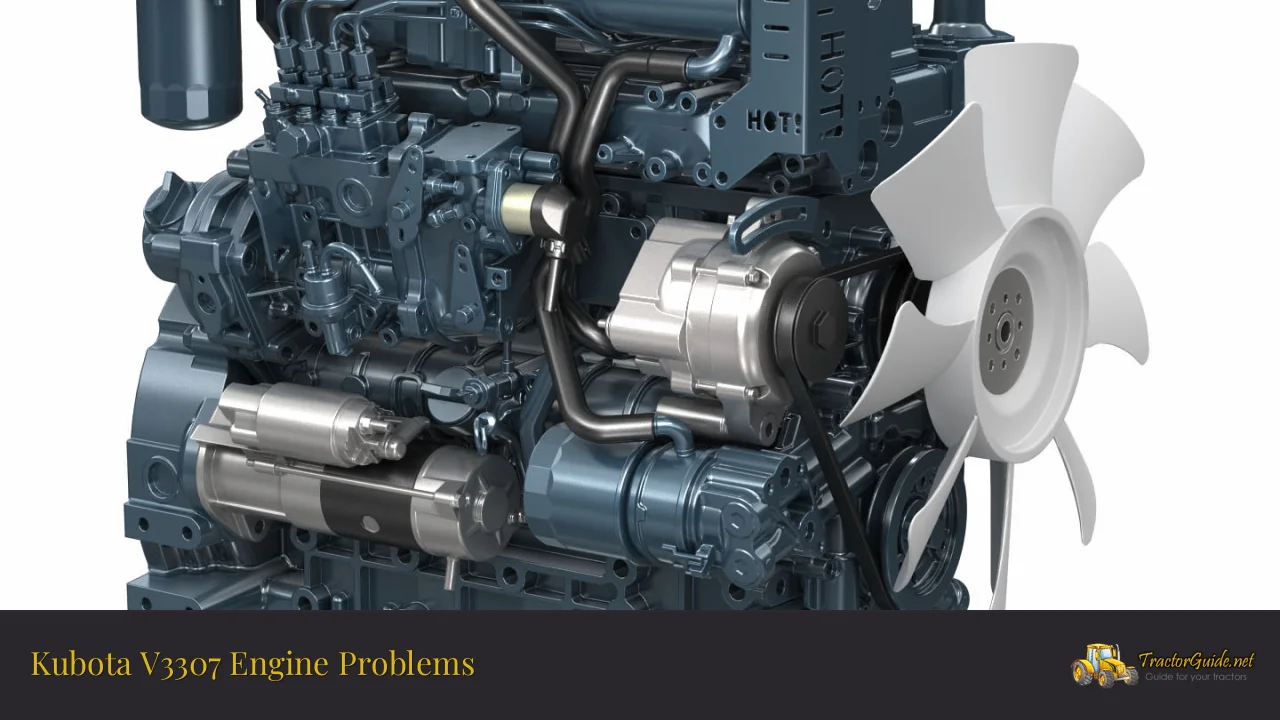

The Kubota V3307 engine is a robust, four-cylinder diesel engine known for its reliability and efficiency in various applications, including agricultural and construction machinery. Despite its reputation, users may encounter several common problems that can affect performance and longevity. Understanding these issues, their symptoms, and potential solutions is crucial for maintaining optimal engine function.

The V3307 engine features a displacement of 3.3 liters and produces a maximum output of approximately 74.3 HP at 2600 RPM. It employs advanced technologies such as a common rail fuel injection system and a turbocharged aspiration to enhance performance while complying with stringent emissions regulations. However, like any engine, it is not immune to problems that can arise during operation.

| Common Problems | Symptoms |

|---|---|

| Overheating | Steam or warning light activation |

| Oil leaks | Visible oil stains or low oil levels |

| Power loss | Sluggish performance under load |

| Unusual noises | Knocking or grinding sounds |

| Warning lights illuminated | Check engine light or other alerts |

Common Problems with the Kubota V3307 Engine

The Kubota V3307 engine can experience several issues that may hinder its performance. Recognizing these problems early can save time and money on repairs.

- Overheating: This is one of the most frequent issues reported by users. Overheating can occur due to a variety of factors, including a clogged radiator, a malfunctioning thermostat, or a failed water pump. If not addressed promptly, overheating can lead to severe damage, such as warped cylinder heads or complete engine failure.

- Oil Leaks: Oil leaks can originate from worn gaskets, seals, or threaded joints. Identifying the source of an oil leak is essential to prevent further damage. A significant loss of oil can lead to insufficient lubrication, increasing wear on internal components.

- Power Loss: Users may notice decreased power output from the engine, particularly under load. This can be caused by clogged air filters, malfunctioning injectors, or exhaust blockages. Regular maintenance of the fuel and air systems is vital to ensure optimal performance.

- Unusual Noises: Knocking or grinding sounds often indicate mechanical wear within the engine. These noises could stem from worn bearings or issues with the timing chain. Addressing these noises early can prevent more extensive damage.

- Warning Lights: The presence of warning lights on the dashboard indicates that the engine management system has detected a fault. Common causes include faulty sensors or electrical issues that require immediate attention.

Diagnosing Engine Issues

Proper diagnosis is critical for addressing problems with the Kubota V3307 engine effectively. Users should follow a systematic approach when diagnosing issues:

1. Visual Inspection: Start by examining the exterior of the engine for any visible signs of damage, such as cracks in the block or head.

2. Check Fluid Levels: Ensure that oil and coolant levels are adequate. Low levels can lead to overheating and increased wear.

3. Monitor Performance: Pay attention to any changes in power output or unusual noises during operation.

4. Scan for Fault Codes: Use an OBD-II scanner to check for any fault codes stored in the engine management system.

5. Conduct Pressure Tests: Perform pressure tests on the cooling system to identify leaks or failures in components like the water pump.

By following these steps, users can identify potential issues before they escalate into more significant problems.

Practical Solutions for Common Problems

Addressing common problems with the Kubota V3307 engine requires both preventive measures and reactive solutions:

- Preventive Maintenance: Regular maintenance is crucial for preventing many common issues. This includes changing oil and filters, cleaning air filters, and inspecting cooling systems regularly.

- Cleaning Radiators: If overheating is an issue, ensure that the radiator is free from debris that may obstruct airflow. Cleaning out dirt and dust from radiator fins can significantly improve cooling efficiency.

- Repairing Oil Leaks: For oil leaks, identify the source and replace worn gaskets or seals as necessary. Tightening loose fittings may also help mitigate minor leaks.

- Replacing Filters: Clogged air or fuel filters should be replaced promptly to restore proper airflow and fuel delivery to the engine.

- Professional Assistance: For complex problems such as unusual noises or persistent warning lights, it may be best to consult with a professional mechanic who specializes in diesel engines.

Performance Characteristics of the V3307 Engine

The Kubota V3307 engine is designed with several performance characteristics that enhance its functionality across various applications:

- Power Output: With a maximum output of approximately 74.3 HP, this engine provides sufficient power for heavy-duty tasks in construction and agriculture.

- Fuel Efficiency: The advanced common rail direct injection system optimizes fuel combustion, leading to improved fuel efficiency and reduced emissions.

- Noise Level: The design incorporates noise reduction measures that contribute to lower operational noise levels, enhancing user comfort during operation.

- Durability: Known for its reliability, the V3307 engine performs well under challenging conditions while maintaining a long service life when properly maintained.

Importance of Regular Maintenance

Regular maintenance is essential for ensuring the longevity and reliability of the Kubota V3307 engine. Key maintenance practices include:

- Changing oil and filters at recommended intervals

- Inspecting belts and hoses for wear

- Checking coolant levels and ensuring proper cooling system function

- Monitoring fuel quality to prevent injector issues

- Keeping air filters clean to maintain airflow

By adhering to a consistent maintenance schedule, users can mitigate many common problems associated with this engine model.

FAQs About Kubota V3307 Engine Problems

FAQs About Kubota V3307 Engine Problems

- What are common symptoms of problems in a Kubota V3307 engine?

Common symptoms include overheating, oil leaks, decreased power output, unusual noises, and warning lights. - How can I prevent overheating in my Kubota V3307?

Regularly clean the radiator and ensure coolant levels are adequate to prevent overheating. - What should I do if I notice an oil leak?

Identify the source of the leak and replace worn gaskets or seals promptly. - How often should I perform maintenance on my V3307 engine?

Follow manufacturer guidelines for maintenance intervals; typically every 100 hours of operation. - When should I consult a professional mechanic?

If you encounter persistent issues such as unusual noises or warning lights that you cannot diagnose yourself.

In conclusion, while the Kubota V3307 engine is designed for durability and efficiency, it is vital to remain vigilant regarding potential issues that may arise during operation. By understanding common problems and implementing effective maintenance strategies, users can ensure their engines operate smoothly and efficiently for years to come.

Citations:

[1] https://www.kubotaengine.com/kubota-07-series-engines-your-source-of-proven-reliability/

[2] https://global.engine.kubota.co.jp/en/products/detail/71/

[3] https://tractordetails.net/kubota-v3307-engine-problems/

[4] https://www.youtube.com/watch?v=3JzgHwCVZIA

[5] https://www.countrysalesandservice.com/maintenance/common-kubota-tractor-and-diesel-engine-problems-and-solutions/

[6] https://blog.yemparts.com/2024/03/01/in-depth-analysis-of-kubota-v3307-engine-performance-characteristics-wide-application-and-maintenance-recommendations/

[7] https://www.orangetractortalks.com/forums/threads/engine-problems-where-to-start-looking.16530/

[8] https://dieselexperts.net/product/kubota-v3307-engine/