The Massey Ferguson 135 tractor, introduced in 1964, has become an icon in the world of agriculture. Known for its reliability, versatility, and ease of use, this tractor has left an indelible mark on farms across the globe. In this comprehensive guide, we’ll explore the various aspects of the MF 135, including its features, maintenance, and the enduring legacy that has made it a favorite among farmers for generations.

A Brief History of the Massey Ferguson 135

The Massey Ferguson 135 was born out of the merger between Massey-Harris and Ferguson companies in 1953. This union brought together the best of both worlds, combining Massey-Harris’s manufacturing prowess with Ferguson’s innovative designs. The MF 135 was introduced as part of the 100 series, which aimed to provide farmers with reliable, efficient, and versatile machinery.

Key Features and Specifications

The Massey Ferguson 135 came equipped with several features that set it apart from its contemporaries:

| Feature | Specification |

|---|---|

| Engine Options | Perkins 3-cylinder diesel or Continental gas engine |

| Horsepower | 45.5 HP (diesel) / 45 HP (gas) |

| Transmission | 6 forward and 2 reverse gears |

| Hydraulic System | Category I and II three-point hitch |

| PTO | 540 rpm |

| Weight | Approximately 2,500 lbs (1,134 kg) |

Engine Options

One of the most notable aspects of the MF 135 was its engine options. Farmers could choose between:

- Perkins 3-cylinder diesel engine: Known for its fuel efficiency and reliability, this engine became a favorite among many farmers.

- Continental gas engine: While less popular than the diesel option, it still provided ample power for various farming tasks.

Transmission and Hydraulics

The MF 135 featured a robust transmission system with 6 forward and 2 reverse gears, providing flexibility for various farming operations. Its hydraulic system was equally impressive, supporting both Category I and II three-point hitches, making it compatible with a wide range of implements.

Operational Guidelines

To get the most out of your Massey Ferguson 135, consider the following operational tips:

- Pre-operation checks: Before starting your tractor, always check fluid levels, tire pressure, and overall condition.

- Proper warm-up: Allow the engine to warm up for a few minutes before engaging in heavy work, especially in cold weather.

- Implement attachment: Ensure all implements are correctly attached and secured before operation.

- Gear selection: Choose the appropriate gear for the task at hand to maximize efficiency and minimize wear on the tractor.

- Hydraulic operation: Familiarize yourself with the hydraulic controls and their functions to operate attachments effectively.

Maintenance Tips

Regular maintenance is crucial for keeping your MF 135 in top condition. Here are some essential maintenance tasks:

Engine Maintenance

- Oil changes: Change the engine oil and filter every 100-150 hours of operation or at least once a season.

- Air filter: Clean or replace the air filter regularly to ensure optimal engine performance.

- Fuel system: Check and clean the fuel filter periodically, and drain water from the fuel system as needed.

Transmission and Hydraulic System

- Fluid checks: Regularly inspect transmission and hydraulic fluid levels, topping up as necessary.

- Filter replacement: Replace transmission and hydraulic filters according to the manufacturer’s recommendations.

Cooling System

- Radiator maintenance: Keep the radiator clean and free of debris to prevent overheating.

- Coolant checks: Inspect coolant levels and condition regularly, replacing as needed.

Electrical System

- Battery care: Keep battery terminals clean and check electrolyte levels in non-sealed batteries.

- Wiring inspection: Regularly inspect wiring for wear or damage, replacing as necessary.

Power Steering System

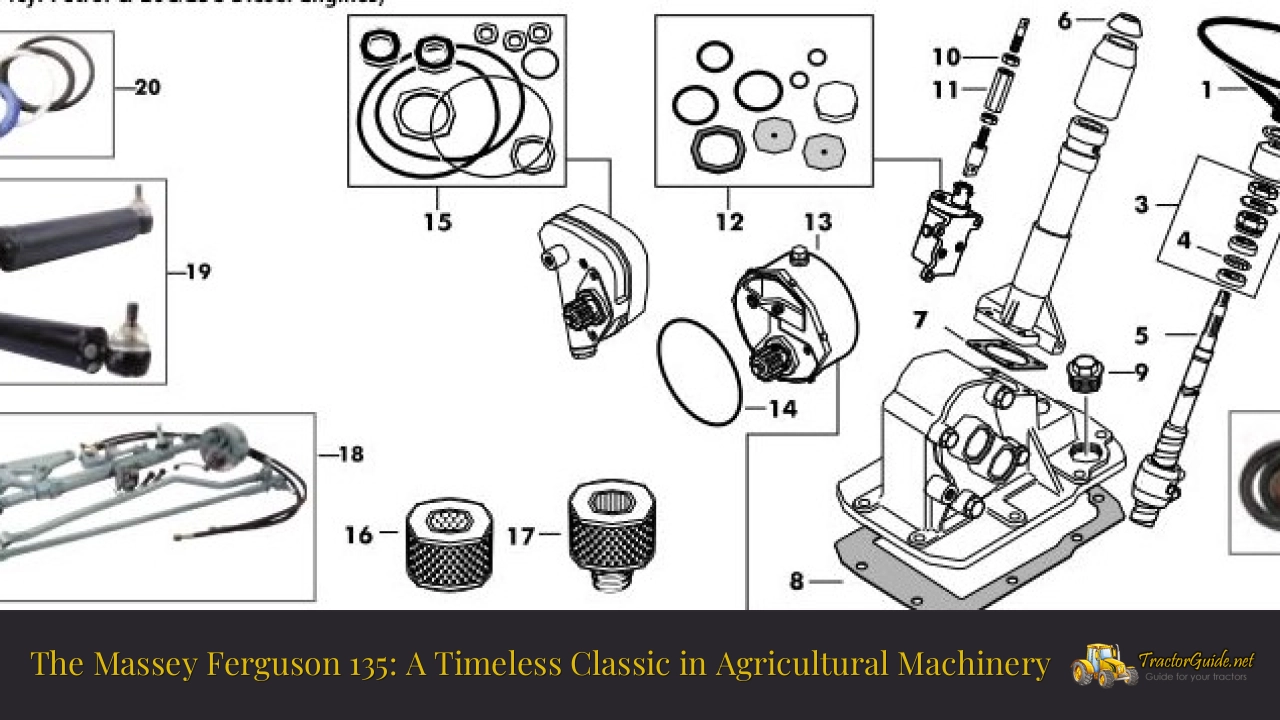

The power steering system on the Massey Ferguson 135 is a crucial component that enhances the tractor’s maneuverability and ease of use. Understanding its parts and maintenance is essential for optimal performance.

Key Components

- Power Steering Pump: This is the heart of the power steering system, providing hydraulic pressure to assist in steering.

- Steering Column: Connects the steering wheel to the steering mechanism.

- Steering Cylinder: Converts hydraulic pressure into mechanical force to turn the wheels.

- Control Valve: Directs hydraulic fluid flow based on steering input.

- Reservoir: Holds the hydraulic fluid for the power steering system.

Maintenance of Power Steering System

- Fluid checks: Regularly inspect and top up power steering fluid.

- Hose inspection: Check for leaks or wear in power steering hoses.

- Steering alignment: Periodically check and adjust steering alignment if necessary.

User Testimonials

The Massey Ferguson 135’s reputation is best illustrated through the experiences of those who have used it. Here are a few testimonials from long-time users:

“I’ve had my MF 135 for over 30 years, and it’s never let me down. It’s perfect for my small farm operations.” – John D., Ohio

“The fuel efficiency of the Perkins diesel engine is remarkable. It’s a workhorse that doesn’t break the bank.” – Sarah M., UK

“Easy to maintain and parts are readily available. It’s a tractor that’s stood the test of time.” – Robert L., Australia

The Legacy of the Massey Ferguson 135

The MF 135 has left an indelible mark on the agricultural industry. Its combination of reliability, versatility, and user-friendliness has made it a favorite among farmers for decades. Even today, many of these tractors are still in active service, testament to their durability and the quality of their design.

The influence of the MF 135 can be seen in modern Massey Ferguson tractors, which continue to embody the principles of efficiency and reliability that made the 135 so popular.

Conclusion

The Massey Ferguson 135 stands as a testament to excellent engineering and design in agricultural machinery. Its enduring popularity is a result of its reliability, versatility, and ease of maintenance. Whether you’re a hobby farmer or managing larger operations, the MF 135 continues to be a valuable asset in the world of agriculture.

For those considering purchasing a used MF 135 or maintaining an existing one, understanding its features, operation, and maintenance requirements is crucial. With proper care, this classic tractor can continue to serve faithfully for many years to come.

FAQs

What makes the Massey Ferguson 135 so popular?

Its reliability, versatility, and ease of maintenance have made it a favorite among farmers for decades.

How often should I change the oil in my MF 135?

Change the oil every 100-150 hours of operation or at least once a season.

Can I still find parts for the Massey Ferguson 135?

Yes, parts are still widely available due to the tractor’s popularity and long production run.

What is the best engine option for the MF 135?

The Perkins 3-cylinder diesel engine is widely regarded as the best option for its fuel efficiency and reliability.

Is the Massey Ferguson 135 suitable for small farms?

Yes, its compact size and versatility make it ideal for small to medium-sized farming operations.

I recently had to replace the power steering belt on my Massey Ferguson 135, and I was so thankful to have this diagram to help me locate the parts I needed. It made ordering so much easier, and I was able to get the parts in a timely manner. I think it’s a great resource for anyone who needs to replace or upgrade their power steering components. It’s also great that it’s so easy to search for the parts you need on the shop page. I’m thankful for this diagram and the shop page, and I’m sure other users will be too!