Are you noticing Warning Lights on the Hydraulic Oil Case on your Skid Steer? Don’t wait until it’s too late – take action now and ensure your machine is in top condition. Check your oil case and ensure it is functioning correctly to avoid costly repairs in the future.

👀Look at this: Using Teflon Tape on Hydraulic Fittings

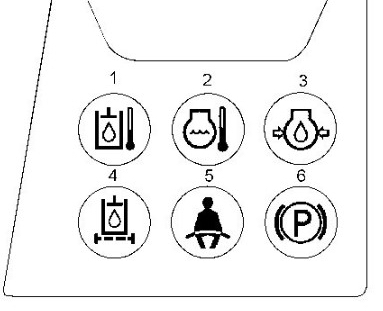

Troubleshoot Your Hydraulic Oil Case Skid Steer Warning Lights Before It’s Too Late

Are you noticing Warning Lights on the Hydraulic Oil Case on your Skid Steer? If so, it’s essential to act now and ensure your machine is in top condition. Ignoring these Warning Lights can lead to expensive repairs down the road. In this article, we’ll provide helpful advice on troubleshooting your Hydraulic Oil Case Skid Steer Warning Lights, so you can avoid costly repairs and keep your machine in top condition.

| Situation | Action |

|---|---|

| The machine is not in use | Check hydraulic oil levels, and replace them if needed |

| The machine is in use | Check for air in the hydraulic system, bleed if needed |

| Oil levels are low | Check for leaks and repair as necessary |

| Warning Lights remain on | Contact a professional mechanic for assistance |

Checking the Oil Level

When you see the warning lights on your hydraulic oil case, you must check the oil level immediately. The oil level should be between the minimum and maximum mark on the dipstick. If the oil level is too low, add oil to bring it up to the correct level.

Checking the Oil Quality

The oil quality is also essential to ensure your skid steer is running correctly. It’s important to use the correct type of oil for your machine and to regularly check the oil for any contaminants or signs of wear. If the oil appears cloudy or has metal particles, it’s time to replace it.

👀Look at this: Bobcat T190 Hydraulic Problems

Inspecting the Lines and Fittings

Inspecting the lines and fittings for any signs of damage or leaks is also essential. Ensure all the pipes and fittings are correctly connected and leak-free. If you find any issues, replace the parts immediately to ensure your machine runs appropriately.

Replacing the Oil Filter

Finally, it’s essential to replace the oil filter on your skid steer regularly. The oil filter removes any contaminants from the oil, so keeping it clean and in good condition is necessary. Make sure to replace the filter every few months or as the manufacturer recommends.

By taking these steps, you can ensure that the hydraulic oil case on your skid steer is in good condition and functioning correctly. Regularly checking the oil level, quality, and filter and inspecting the lines and fittings can help prevent costly repairs in the future. With the help of these simple steps, you can keep your machine running smoothly and safely with the use of hydraulic oil case skid steer warning lights.

Key Takeaways for Troubleshooting Hydraulic Oil Case Skid Steer Warning Lights

- Check the oil level and ensure it is between the minimum and maximum marks on the dipstick.

- Check the oil quality and make sure it is the correct type for your machine.

- Inspect the lines and fittings for any signs of damage or leaks.

- Replace the oil filter regularly.

- Contact a professional mechanic if the Warning Lights remain on.

⚡️Another article: John Deere Hydraulic Pump Problems

Protect Your Skid Steer with Regular Maintenance and Troubleshooting

Regularly checking the oil level, quality, and filter and inspecting the lines and fittings can help protect your skid steer from costly repairs in the future. Paying attention to the hydraulic oil case skid steer warning lights is essential to keep your machine running smoothly and safely. These simple steps will help you get the most out of your skid guide and ensure your device is in top condition. If the warning lights remain on, contacting a professional mechanic is best to diagnose any potential issues.