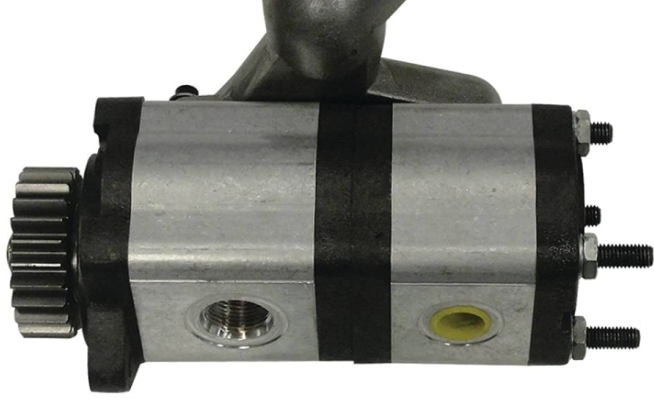

John Deere hydraulic pumps are essential components of many pieces of equipment. However, they can be prone to problems. This guide will explore the various issues associated with John Deere hydraulic pumps and provide troubleshooting solutions to get your equipment running again.

📢Read also: John Deere Dash Light Meanings

Troubleshooting John Deere Hydraulic Pump Problems

From leaks and component failures to pressure and capacity issues, this guide provides comprehensive advice to help you diagnose and repair John Deere hydraulic pump issues quickly and effectively. Learn the common causes of problems and discover the preventive measures you can take to protect your equipment and keep it running smoothly for years to come. Find out how to identify symptoms, troubleshoot issues, and repair components, as well as helpful tips for maintaining a healthy John Deere hydraulic pump.

👀Look at this: John Deere Kawasaki Engine Problems

| Issue | Symptoms | Troubleshooting | Repair |

|---|---|---|---|

| Leakage | Oil residue on the exterior of the pump, decrease in fluid pressure | Check for loose or broken seals, inspect hoses and connections | Replace seals and hoses, tighten connections |

| Component Failure | Noisy pump, decrease in fluid pressure | Check for worn or damaged parts, inspect for debris or contaminants | Replace components, clean or flush the system |

| Pressure Issues | Intermittent or low pressure, slow response times | Check for clogged filters or blocked hoses, and inspect for kinks or bends | Replace filters and hoses, repair kinks or bends |

| Capacity Issues | Reduced flow rate, increased heat | Check for worn parts, and inspect for air leaks or pressure drops | Replace worn parts, repair air leaks or pressure drops |

Seized Pumps

A seized pump is one of the most common John Deere hydraulic pump problems. This occurs when the pump’s internal components become jammed or stuck, preventing the pump from functioning. If left unchecked, a seized pump can cause further damage to the system, leading to more costly repairs. John Deere recommends inspecting the pump and its components for signs of wear or damage and checking for any blockages that could be preventing fluid flow. John Deere suggests that a seized pump can be quickly identified and resolved with the help of experienced mechanics.

Vibration Problems

Vibration problems are another common issue with John Deere hydraulic pumps. Excessive vibration can cause wear and tear on the pump’s internal components, leading to premature failure. To prevent this, John Deere recommends checking the pump for any signs of misalignment or bent components and inspecting the pump for any signs of wear or damage. Additionally, the pump should be inspected for any blockages that could be preventing fluid flow. By taking the necessary steps to identify and resolve vibration problems in John Deere hydraulic pumps, costly repairs, and downtime can be avoided.

Leakage

Leaks can also be a problem with John Deere hydraulic pumps. Leaks can occur for various reasons, including worn seals, loose bolts, or cracked pump housing. If a leak is found, John Deere recommends replacing the seals and bolts and inspecting the pump housing for any cracks or damage. Additionally, the pump should be inspected for any signs of wear or damage and for any blockages that could be preventing fluid flow. Regularly inspecting and maintaining John Deere hydraulic pumps can prevent costly repairs and downtime due to leakage.

📢Read also: John Deere Rsx 850i Problems

Key Takeaways for Troubleshooting John Deere Hydraulic Pump Problems

- Understand the common issues associated with John Deere hydraulic pumps, including leakage, component failure, pressure issues, and capacity issues.

- Be aware of the symptoms of each issue, including oil residue, decrease in fluid pressure, noisy pumps, intermittent or low pressure, and reduced flow rate.

- Identify the troubleshooting methods, such as checking for loose or broken seals, inspecting hoses and connections, checking for worn or damaged parts, and inspecting for debris or contaminants.

- Learn the repair methods, including replacing seals and hoses, tightening connections, replacing components, and cleaning or flushing the system.

- Know the preventive measures you can take, such as regularly inspecting and maintaining the pump, checking for clogged filters or blocked hoses, and replacing worn parts.

- Be aware of the implications and consequences of John Deere hydraulic pump issues, such as further damage to the system and costly repairs.

Benefits of Regularly Maintaining John Deere Hydraulic Pumps

Regularly maintaining John Deere hydraulic pumps is essential for avoiding costly repairs and downtime caused by component failure, leakage, and other issues. By taking the necessary steps to identify and resolve problems, such as inspecting the pump and its components for signs of wear or damage, checking for blockages that could be preventing fluid flow, and replacing seals and bolts, users can ensure their John Deere hydraulic pumps are in optimal condition and running efficiently. Additionally, it is essential to be aware of the implications and consequences of John Deere hydraulic pump issues and the preventive measures you can take to avoid them. With proper maintenance and timely repairs, users can maximize the lifespan of their John Deere hydraulic pump and ensure its safe and reliable operation.

⚡️Other article: John Deere 569 Baler Net Wrap Problems