When it comes to your Case Skid Steer Warning Lights Meaning, it is important to understand the implications of the various lights on your dashboard. Ignoring these warning lights can have serious consequences and can even lead to costly repairs or replacements. By understanding the Case Skid Steer Warning Lights Meaning, you can take the steps necessary to keep your machine running smoothly and safely.

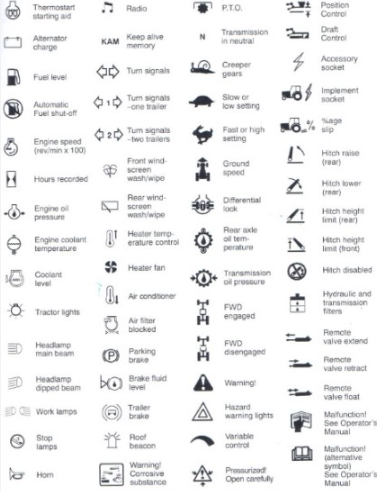

The Case of Skid Steer Warning Lights Meaning can vary from machine to machine and from manufacturer to manufacturer. Generally speaking, there are several common warning lights that you may see on your dashboard. The most common include: Check Engine, Oil Pressure, Coolant Temperature, and Battery. Depending on the model, you may also see additional lights such as Seat Belt, Auxiliary Hydraulic, and Throttle Position. Each of these lights has a unique purpose and it is important to understand the implications of each one. By understanding the Case Skid Steer Warning Lights Meaning, you can take the steps necessary to maintain your skid steer in the best condition possible.

📢Read also: Case Tv380 Problems

Understanding the Case Skid Steer Warning Lights Meaning

| Warning Light | Explanation |

|---|---|

| Check Engine | Indicates a problem with the engine or other related parts. |

| Oil Pressure | Indicates a problem with the oil pressure in the engine. |

| Coolant Temperature | Indicates a problem with the temperature of the coolant. |

| Battery | Indicates a problem with the battery. |

| Seat Belt | Indicates that the seat belt is either not engaged or needs to be replaced. |

| Auxiliary Hydraulic | Indicates a problem with the auxiliary hydraulic system. |

| Throttle Position | Indicates a problem with the throttle position. |

⚠️ What the Different Case Skid Steer Warning Lights Mean

The most common warning lights that you may see on your dashboard include the Check Engine, Oil Pressure, Coolant Temperature, and Battery lights. These lights indicate a potential problem with the engine or other related parts, oil pressure in the engine, the temperature of the coolant, or the battery itself.

⚡️Other article: Case Tr270 Problems

⚠️ Why It’s Important to Understand the Case Skid Steer Warning Lights Meaning

By understanding the Case Skid Steer Warning Lights Meaning, you can take the steps necessary to keep your machine running smoothly and safely. Ignoring these warning lights can have serious consequences, such as costly repairs or replacements. Therefore, it is important to take the time to understand the implications of each warning light on your dashboard.

📢Read also: Case 1840 Problems

🔌 Taking the Steps to Maintain Your Skid Steer in the Best Condition Possible

In order to maintain your skid steer in the best condition possible, it is important to understand the Case Skid Steer Warning Lights Meaning and take the necessary steps to address any issues that may arise. This may include checking the engine, oil pressure, coolant temperature, battery, and other related parts. Additionally, you should also check your seat belt and auxiliary hydraulic systems, as well as the throttle position, to ensure that everything is in working order. Taking the time to understand and address any issues that may arise can help to keep your skid steer running smoothly and safely.